Hyparschale Magdeburg

Built in 1969, the Hyparschale in Magdeburg is one of about fifty shell buildings by structural engineer Ulrich Müther that are still in existence. After standing vacant for over twenty years, the badly dilapidated multipurpose hall was comprehensively restored and converted to plans by gmp. The work was commissioned by the authorities of the state capital of Magdeburg and took place from 2019 to 2024.

The design objective was to revive the Hyparschale, which was listed in 1998, as a multifunctional event and exhibition venue, with the main emphasis on enhancing the interior effect of the shell roof. As part of the refurbishment, the loadbearing capacity of the roof has been restored and even increased with the help of carbon concrete.

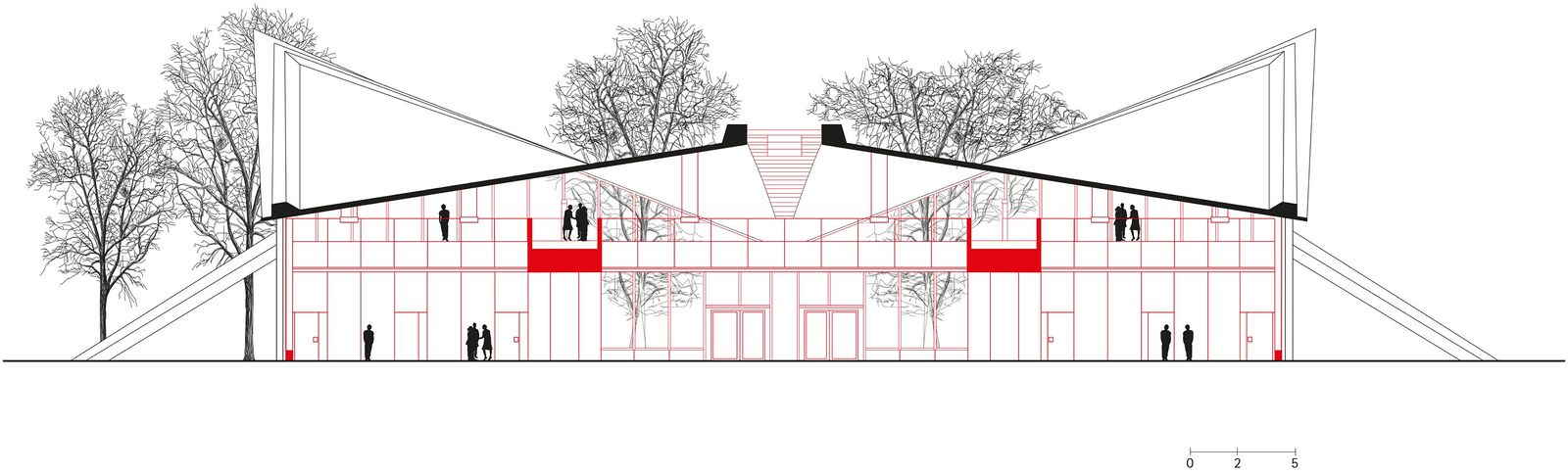

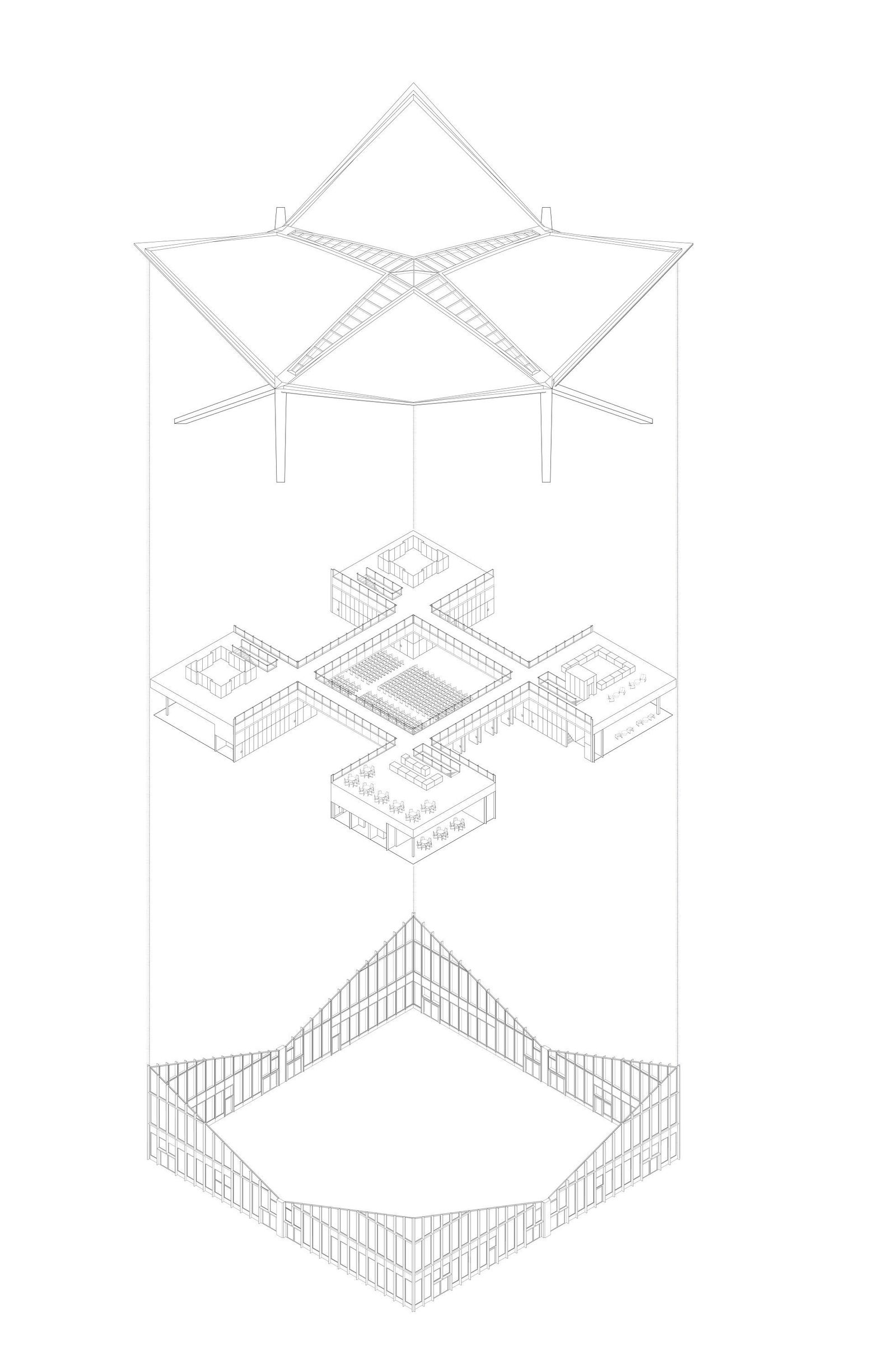

In addition, the rooflights running between the shells were reopened. New cubic structures at the periphery of the interior leave a large open space in the center from where the imposing space under the curved roof can be appreciated; pedestrian bridges between the galleries on the cubes further enhance the experience.

New Invention in Harmony with the Original Idea

It took two interventions to save the ruins of Ulrich Müther’s Hyparschale in Magdeburg from demolition and to reinstate its usefulness for the future. The loadbearing capacity of the visionary roof shell was restored and even improved thanks to state-of-the-art carbon concrete technology. The large interior has been subdivided into smaller rooms for more flexible use, without diminishing the imposing impression created by the sculptural effect of the roof.

New Spatial and Functional Concept

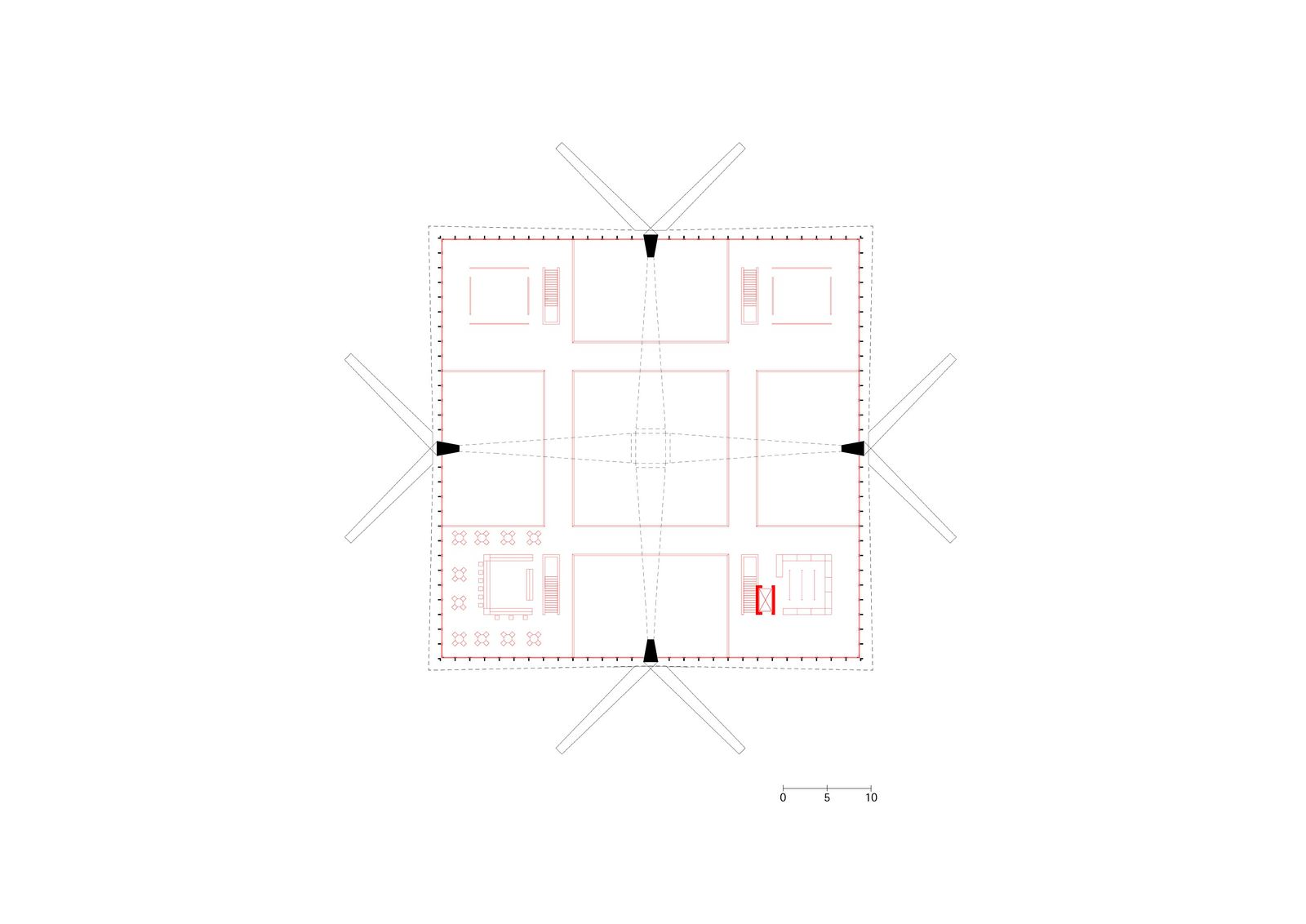

The new structures inside the hall, which follow Müther’s square grid design, provide a rich experience of the open space beneath the curved roof. To create the detailed room schedule requested by the client, the design includes four cubes in the corners of the hall, each with a floor area of 15 x 15 meters.

These cubes feature galleries that are linked by bridges. The flexible layout provides rooms that can be combined for smaller events, seminars, exhibitions, and eateries in the periphery of the large event space for up to 500 people in the center of the hall.

New Sweep

On the four cubes there are open, multifunctional spaces from where the grand gesture of the sweeping roof by Ulrich Müther can not only be seen but also appreciated from a much closer standpoint. From here, visitors have an open view of the concrete shell roof with its ribbon-shaped rooflights, which have been reopened as part of the refurbishment. As originally intended, these ribbons of light once again emphasize the shape of the shell and provide optimal lighting to the center of the hall.

The star-shaped rooflight, created by the gaps between the joints of the four hyperbolic concrete shells, has been reopened for the first time. Originally, the gaps had been filled with glass bricks but, due to leakages, they were closed shortly after the building’s completion.

"A basic prerequisite of any successful conversion is an appreciation for what others created in the past."

In terms of construction and design, the new interior structures are reminiscent of the original external facade with its vertical emphasis and industrial steel and glass materials.

The new transparent glass facade opens up views to and from Rotehornpark and replaces the former translucent industrial glazing while retaining the original facade structure.

At the center of the hall, the height from the floor to the roof is 12 meters and at the corners of the building, it is nearly 16 meters. Below ground, tie beams connect the four shells to ensure the structural integrity of the building.

Construction of the Shell Roof (1969)

The original construction of the shell roof was carried out by Gerling & Rausch, who used sprayed concrete as directed by Ulrich Müther. The operatives used the so-called Torkret process, in which spray pumps were used to apply a concrete layer of a thickness of only seven centimeters on to the wooden shuttering, proceeding from one quadrant to the next. Remarkably, the concrete for each of the four hyperbolic paraboloids was sprayed on in one contiguous area without any interruption in the process.

Reinforcement with Carbon Concrete

During the first phase of the refurbishment of the Hyparschale from 2019 to 2021, the loadbearing capacity of the roof was restored and even increased by fifty percent. Originally, the thickness of the shell was only seventy millimeters; as a result of the use of carbon concrete, it was possible to reinstate the shell at the same thickness. In a process specially developed for the Magdeburg Hyparschale, the flexible bonding material reinforces both the inside and outside surfaces of the shell roof, thereby protecting it against corrosion.

Similarly, during the refurbishment, concrete was applied to the four roof segments one at a time, thus allowing time for the preparation of the other segments in parallel.

Following an analysis of the existing fabric, a sustainable and sensitive concept for the carbon concrete-based refurbishment was developed. This material consists of fine-grained concrete reinforced with non-metallic carbon mesh. Extremely fine carbon fibers are spun into yarns and woven into a mesh with a grid structure. These meshes can be varied in their loadbearing capacity, flexibility, and formability. In contrast to steel-reinforced concrete, in which the concrete layer has to protect the reinforcement from corrosion, this material can be used to create particularly lightweight and elegant structures with greater loadbearing capacity.

"Dealing with postwar buildings is particularly challenging, especially when they are already listed as historic monuments. In these cases, the issues are less about construction methods associated with traditional craftsmanship than about construction that uses industrially manufactured elements for which the production lines no longer exist."

Review: 1969-2017

The Hyparschale Magdeburg is the largest remaining hall roof by a man who was arguably East Germany’s most inventive structural engineer, Ulrich Müther, (1934 – 2007). His trademark was double-curved roof surfaces, or “hyperbolic paraboloids”, which are self-bracing thanks to their own curvature, allowing the roof to span extremely wide spaces without columns and using very little material — a concept for which Müther coined the term “Hyparschale”.

The term “Hyparschale” refers to a shell roof construction consisting of hyperbolic paraboloids. The structure in Magdeburg consists of four regular double-curved concrete shells that cover an area of 48 x 48 meters without columns.

For his Magdeburg Hyparschale, Müther pushed the technical possibilities of his day to their limits. He not only wanted to span a 48-square-meter area with a double-curved roof without supports, but he also wanted to subdivide the roof surface into four equal parts, each suspended over a square floor area and each with a double-curved geometry. In the gaps between these roof segments he installed glass bricks to form ribbon skylights that came together at the center of the hall to form a star-shaped skylight.

Given the technical possibilities at the time, the idea of this star-shaped skylight turned out to be too challenging. Although the roof held up, water leaked through the glass brick ribbons into the hall. In consequence, the skylights were fully covered with roofing felt shortly after the opening. Müther’s intended effect – the transparency, lightness, and fragility of the hall roof – was lost. In the years that followed, the thin concrete roof cracked open in many places, exposing the reinforcement steel to corrosion. In 1997, owing to the risk of collapse, the Hyparschale was condemned and was going to be demolished. Thanks to the protests of citizens and international experts, who recognized the cultural value of this unique building construction, it was ultimately possible to save the hall. Since the authorities of the state capital of Magdeburg were unable to find private investors, they decided in 2017 to undertake the refurbishment of the Hyparschale themselves.

As a result of the new functional concept in combination with conservation requirements the “new” Hyparschale can point the way to the preservation of further works by Müther as well as that of other post-war buildings at risk. It was the deployment of the latest technical processes that made it possible to preserve Müther’s project from 1969 in its original form, respecting his vision and thus ensuring the building’s continued utility.

"However, the preservation of existing buildings is often only possible by implementing bold changes that take into account the need for such buildings to be useful in the future."

Client State Capital of Magdeburg, Eigenbetrieb Kommunales Gebäudemanagement (Department for Communal Facilities Management)

Design (1969) Ulrich Müther, in cooperation with Horst Freytag

Construction (1969) Gerling & Rausch KG

VgV Negotiation Process contract awarded in 2017

Conversion Design Meinhard von Gerkan and Stephan Schütz with Christian Hellmund

Project Leads Sophie von Mansberg, Ursula Köper

Team Rosaria de Canditiis, Jan-Peter Deml (Visualizations) Annett Fabian (BIM), Florian Illenberger, Sonja Kautz, Annette Löber, Bao Wangtao, Maria Wolff, Thilo Zehme (Visualizations), Aaron Zuber

Site Supervision (gmp) Moritz Buchholz, Jessica Neumann, Christoph Rohner, Viktor Saib, in cooperation with A.BB Architects, Rudolf Droste

Structural Engineering / Fire Protection Prof. Rühle, Jentzsch & Partner, Dresden

MEP Haupt Ingenieurgesellschaft, Leipzig; Ingenieurbüro Elektrotechnik Dipl.Ing. Andreas Kist, Burg

Lighting Design Lichtvision Design, Berlin

Acoustics Engineering ADA Acoustics & Media Consultants, Berlin

Guide System Moniteurs GmbH Communication Design, Berlin

Highways, Civil Engineering, Drainage Technology IKM Ingenieurkontor Magdeburg

Building Physics Kriegenburg Consulting Engineers, Magdeburg; ITG Energieinstitut GmbH, Magdeburg

Carbon Concrete Technology CARBOCON, Dresden

Construction Period Phase I 2019–2021, Phase II 2021–2024

GFA 3,948 m²

Capacities

Events Areas 1–4 500 seats

Seminar Rooms 2.1/4.2 127/127 seats