Facelift for Magdeburg Hyparschale

Shell roof is reinforced with carbon concrete

The refurbishment of the listed Hyparschale by Ulrich Müther to a design by Architects von Gerkan, Marg and Partners (gmp) is proceeding. With the beginning of the repairs to the concrete shell roof using an unique carbon concrete technology, the work has now reached the first milestone: the existing shell roof, which has suffered from corrosion, is reinforced inside and outside with only 10 mm-thick layers of the lightweight and particularly flexible compound material that consists of specific carbon fibers and fine-grained concrete, and which even increases its structural strength. Based on this process, which was specifically approved for the Magdeburg Hyparschale, the interior of this building—with its open span under the shell roof—will once again appear in its original form. This is key to the design and refurbishment concept and re-establishes the lightweight feel of the building, as well as its curved shape, while at the same time potentially being instrumental in the preservation of other Müther buildings.

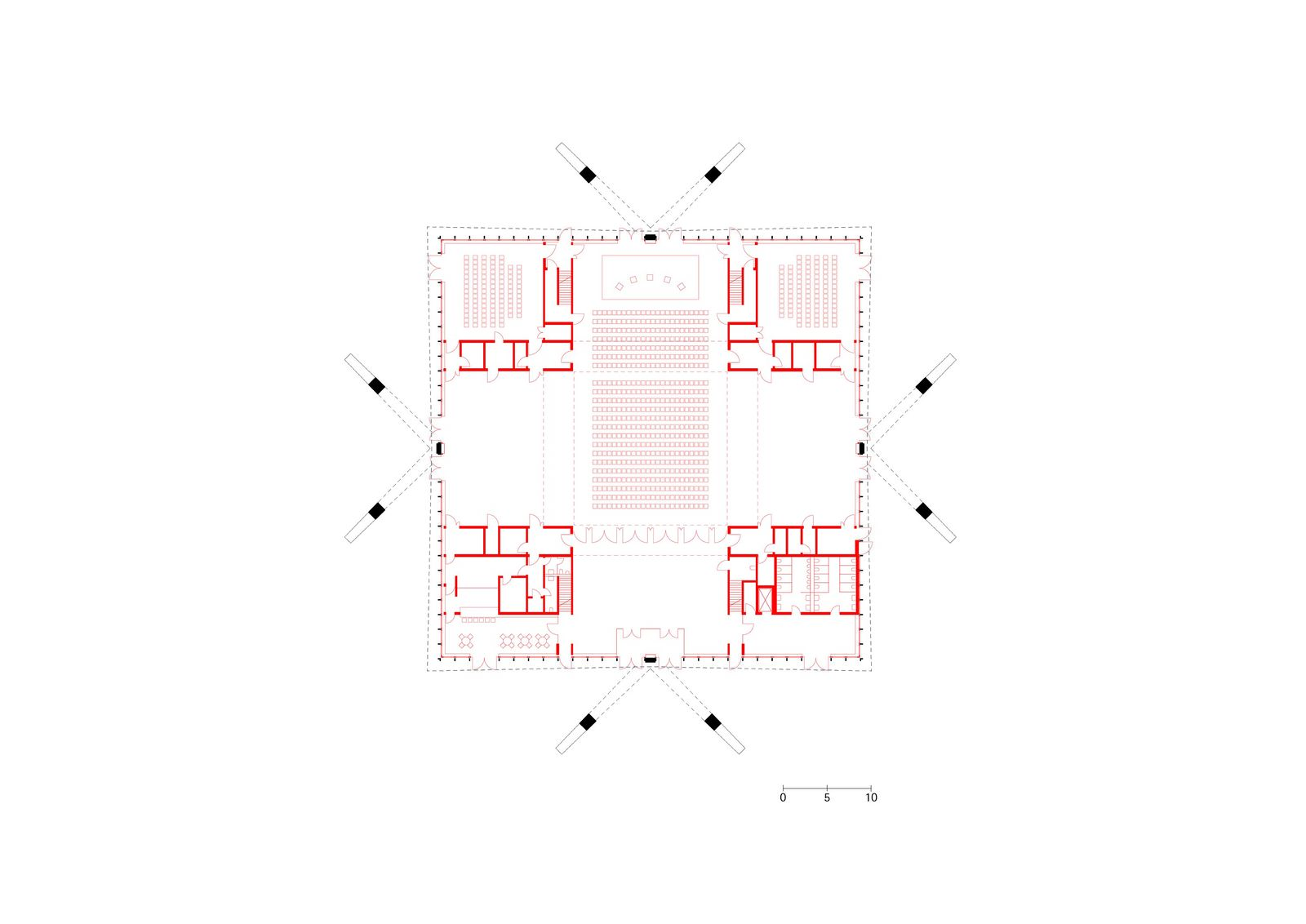

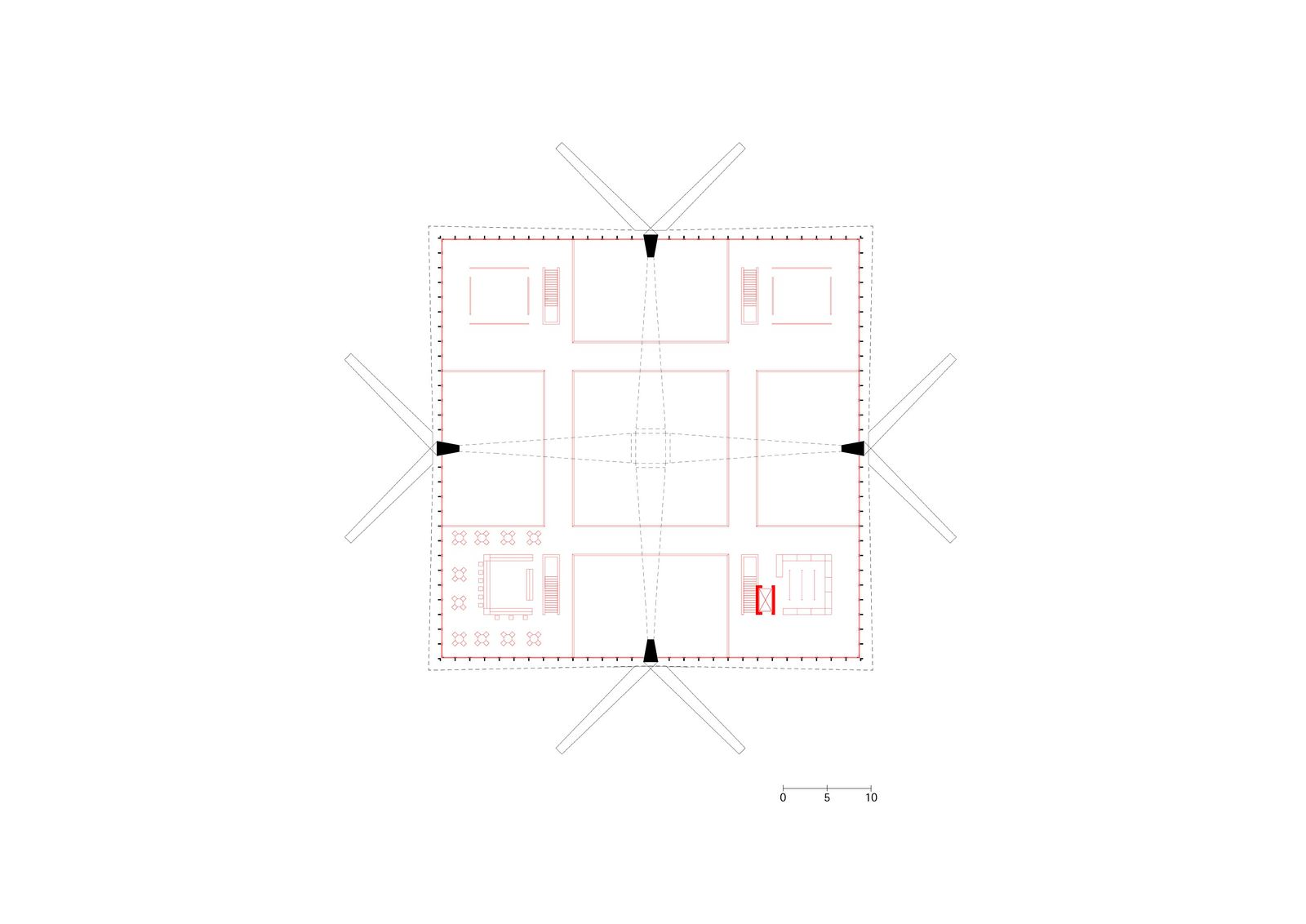

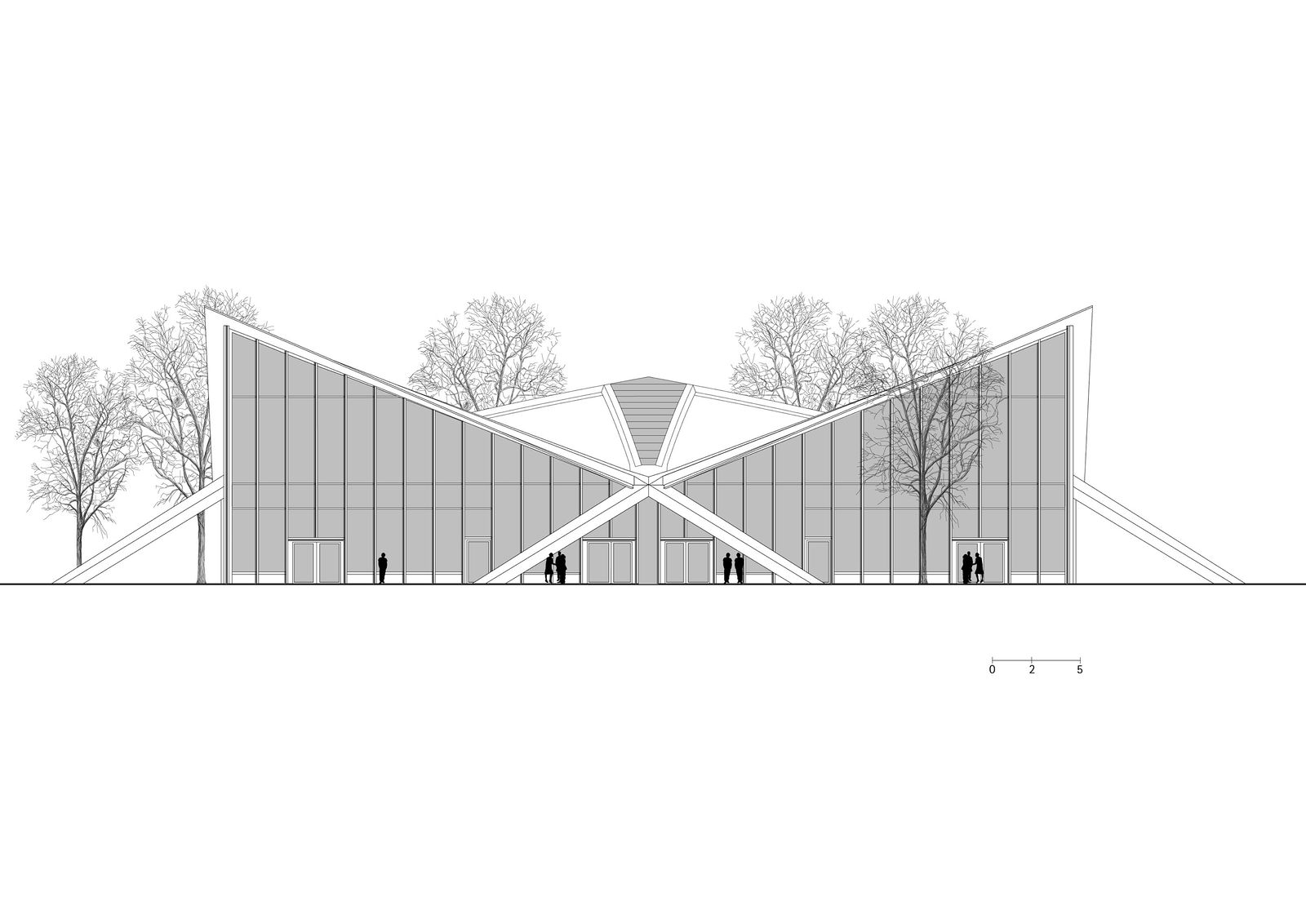

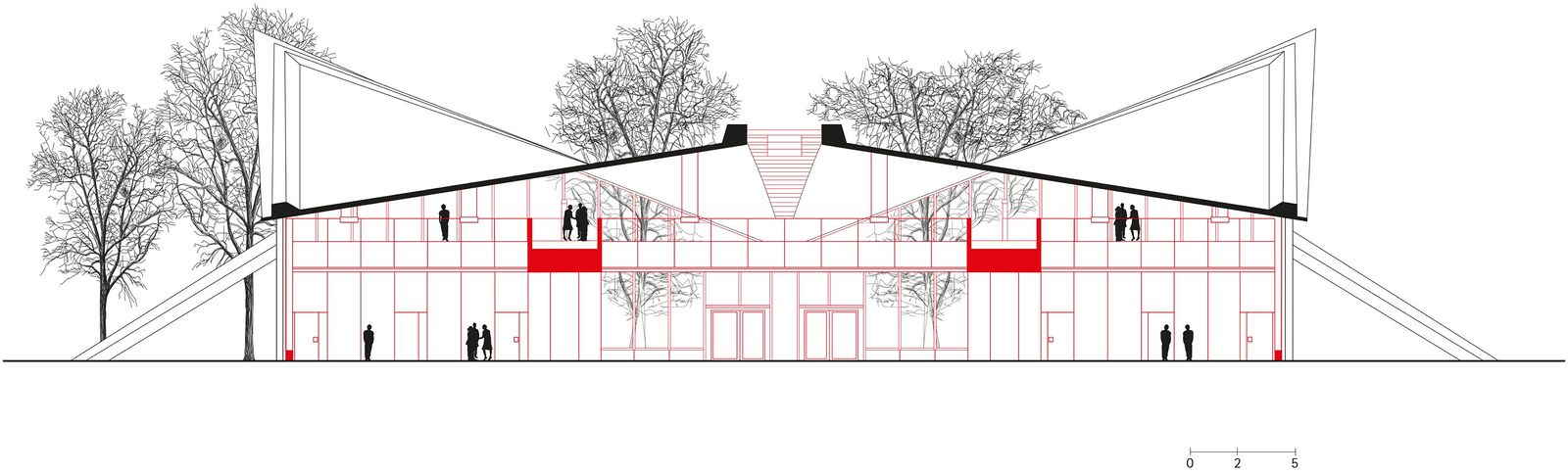

The Hyparschale building in Magdeburg at the eastern bank of the River Elbe, dating from 1969, is one of about fifty still-existing shell buildings by the structural engineer Ulrich Müther, who was instrumental in defining modern architecture in the GDR. Müther’s design for the concrete roof consists of four hyperbolic paraboloids. The roof surfaces with a regular double curvature span an open area of 48 x 48 meters. gmp’s design aims to revive the badly dilapidated multipurpose hall, which has not been used since 1997, to recreate a multifunctional events and exhibition venue.

Following an analysis of the existing fabric, a sustainable and sensitive concept for the carbon concrete-based refurbishment was developed. This material consists of fine-grained concrete reinforced with nonmetallic fibers. Extremely fine carbon fibers are spun into yarns and woven into a mesh with a grid structure. These meshes can be varied in their loadbearing capacity, flexibility, and formability. In contrast to steel-reinforced concrete, in which the concrete layer has to protect the reinforcement from corrosion, this material can be used to create particularly lightweight and elegant structures with greater loadbearing capacity. Using this version, which was only approved for the Magdeburg Hyparschale, it is possible to respond to the specific requirements of this roof. Furthermore, the four separate roof segments facilitate an optimized building sequence: whilst the concrete of one of the quadrants is being poured, the other surfaces are prepared.

In addition, as can be seen already, the design provides for the reopening of the rooflights running crosswise between the shells. These fenestration bands emphasize the shape of the shells and provide optimum lighting to the center of the hall; newly inserted gallery levels and walk-on bridges make it possible to use and experience the open space with its curved roof in many different ways. The interior steel constructions and facades are reminiscent of the original external facade with its vertical emphasis and industrial steel and glass materials. The former translucent industrial glazing is replaced by a transparent glass facade, with the original facade construction being retained.